Swyddogaeth

(1) sythu a lefelu deunydd coil

(2) Llwytho a thorri deunydd cydamserol

(3) Gyriant gwregys a llwytho deunydd yn awtomatig

Manylion Cyflym

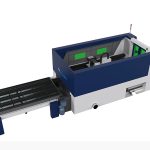

Cais: Torri Laser

Cyflwr: Newydd

Math Laser: Laser Ffibr

Deunydd sy'n Gymwys: Metel

Torri Trwch: 20mm

Ardal Torri: 1500 * 3000mm

Cyflymder Torri: 35m / mun

CNC neu Ddim: Ydw

Modd Oeri: Oeri Dŵr

Meddalwedd Rheoli: Cypcut

Fformat Graffig â Chefnogaeth: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Ardystiad: CE, ISO, SGS, FDA, BV

Gwasanaeth Ôl-werthu a Ddarperir: Peirianwyr ar gael i wasanaethu peiriannau dramor

Swyddogaeth: peiriant torri laser metel cnc

Ardal Weithio: 1300x3000mm

Pwer Laser: 500W ~ 4000W

Max. Cyflymder Symud: 100m / mun

Max. Cyflymder Torri: 35m / mun

Cywirdeb Lleoli: 0.03mm

Cywirdeb Ail-leoli: 0.02mm

Munud. Lled Llinell: 0.1mm

Dyfnder Torri: 0.2-6mm

Gofynion Pwer: 380V / 50Hz / 16A

Nodweddion

(1) Integreiddio deunydd awtomataidd yn sythu, lefelu, llwytho a thorri

(2) Llinell gydosod awtomatig ar gyfer arbed gweithlu

(3) Gwarant parhad ar gyfer cynhyrchu a phrosesu

(4) Torri deunydd coil net i wella cyfradd defnyddio metel dalen.

(5) Cyfluniad compact a dyluniad lloc llawn ar gyfer gweithredu mwy diogel ac ecogyfeillgar.

(6) Llwyfan torri rholio i osgoi jamio deunydd yn ystod trawsgludiad deunydd gorffenedig

(7) Mae peiriant lefelu wedi'i gydamseru â llwyfan torri rholio ar gyfer bwydo deunydd, er mwyn amddiffyn ochr isaf y dechrau wrth fwydo deunydd.

(8) Hwylusir llwytho deunydd yn awtomatig gyda dyfais terfyn lled i atal deunyddiau oddi ar y trywydd iawn o faint cul neu eang a sicrhau aliniad.

Mantais peiriant laser cnc torri metel

1. Ansawdd llwybr rhagorol: dot laser llai ac effeithlonrwydd gwaith uchel, o ansawdd uchel.

2. Cyflymder torri uchel: mae cyflymder torri 2-3 gwaith yn fwy na'r un peiriant torri laser CO2 pŵer.

3. Rhedeg sefydlog: mabwysiadu laserau ffibr mewnforio gorau'r byd, perfformiad sefydlog, gall rhannau allweddol gyrraedd 100,000 awr;

4. Effeithlonrwydd uchel ar gyfer trosi ffotodrydanol: Cymharwch â pheiriant torri laser CO2, mae gan beiriant torri laser ffibr dair gwaith effeithlonrwydd trosi ffotodrydanol.

5. Cost isel: Arbed ynni a diogelu'r amgylchedd. Mae'r gyfradd trosi ffotodrydanol hyd at 25-30%. Defnydd pŵer trydan isel, dim ond tua 20% -30% o beiriant torri laser CO2 traddodiadol ydyw.

6. Cynnal a chadw isel: nid oes angen i'r trosglwyddiad llinell ffibr adlewyrchu lens, arbed cost cynnal a chadw;

7 Gweithrediadau hawdd: trosglwyddiad llinell ffibr, dim addasiad i'r llwybr optegol.