Disgrifiad Manwl o'r Cynnyrch

| Rhif Model: | ACCO ECO-FIBER-1530-6KW | Ystod Gweithio: | 1500x3000mm |

|---|---|---|---|

| Math o Laser: | USA Raycus Fiber YLS-6Kw | Trosglwyddo: | Gear a Rack Taiwan YYC |

| Pen Laser: | Swistir Raytools Auto-ganlynol | System sy'n cael ei gyrru gan fwrdd: | System Modur a Gyrru Siapan Yaskawa Servo |

| Cyfanswm y Defnydd Pwer: | Meddalwedd Torri Laser Proffesiynol Laser Accurl | Geiriau allweddol: | Laser Cutting Machine In Metal |

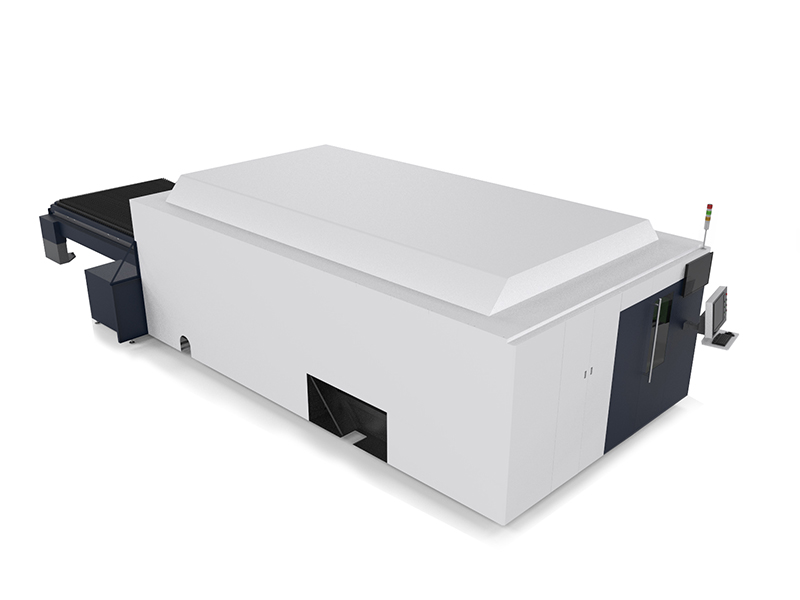

6KW Laser Cutting Machine in 16 mm Aluminyum Alloys metal with Raycus Fiber Laser Power

Cyflwyniad Cynnyrch

Mae Laserau Ffibr ACCURL yn dod â datrysiad cost-effeithiol, cynnal a chadw isel, cost gweithredu isel ac ecogyfeillgar i'ch sefydliad. Mae ein peiriannau laser ffibr yn darparu torri o ansawdd a goddefiannau heb fawr o golled cynhyrchiant rhwng swyddi, sy'n cyfateb i enillion uwch ar fuddsoddiad.

• Gweithgynhyrchir gan bobl sy'n defnyddio eu peiriannau eu hunain

• Trawst laser a drosglwyddir trwy gebl ffibr optig yn hytrach na gyda drychau a thiwbiau sianel sy'n arwain at golli pŵer yn ddibwys.

• Mae gan y ffynhonnell golau laser ddisgwyliad oes o fwy na thair gwaith disgwyliad laser CO2 cyfatebol.

• Cyflymder torri uwch yn bosibl

• Mae tablau cyfnewidiol deuol yn caniatáu ar gyfer llwytho a dadlwytho'n gyflymach, gan leihau amser segur

• Mae tonfedd laser yn un rhan o ddeg o laser CO2

• Gostyngiad mewn torri newidynnau neu wybodaeth lwythol

• Mae Laser Ffibr yn hynod effeithlon, mae'n cyfateb i ddefnydd pŵer isel iawn

• Cost gweithredu isel, llai o gost ynni, nid oes angen nwyon laser i gynhyrchu trawst

• Hyblygrwydd torri uchel (Dur, Dur Di-staen, Pres, Copr, Titaniwm, Alwminiwm, a mwy)

• Ychydig iawn o nwyddau traul

OFFER SAFONOL

• Ffrâm peiriant laser lleddfu straen

• System paled ddeuol sy'n newid yn awtomatig

• Ffynhonnell golau

• Oeri

• System CAD / CAM Radan neu Lantek

• System Rack Precision & Pinion Drive (Wedi'i wneud yn yr Almaen)

• 3 lens amddiffynnol is

• 5 nozzles pob un o'r canlynol: (1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm)

• 3 Addasydd Ffroenell Ceramig

• System ffroenell wedi'i galibro'n awtomatig

• Lens gyda Hyd Ffocws 5.9 ”

• System Casglu Slagiau Clyfar / Cludydd Sglodion

• System Trosglwyddo Trawst Ffibr (Cebl Ffibr)

• Yn gweithredu gyda nwyon N2 ac O2 (torri)

• System Alinio Swyddi Cartref

• Dewisydd Nwy Ategol

• Swyddogaeth Pwysau Nwy Ategol NC

• Rhybudd Myfyrio Auto

• Goleuadau Gweithio

• Lampau Dangosydd Rhybudd

• Pecyn Glanhau Lens

• Offer Tynnu ac Addasu

• Platiau Tir

• Llawlyfrau Defnyddwyr yn Saesneg

OFFER DEWISOL

• Gyriant Llinol

• Uned Casglu Llwch

• Gwydrau Gweithredwyr Ychwanegol

• Lens gyda Hyd Ffocws 7.874 ”

• Systemau llwytho a dadlwytho dalennau

• Systemau Awtomeiddio a Storio

• Newidiwr Ffroenell Awtomatig

• Meintiau bwrdd personol

• Hyd at ffynonellau golau laser laser 6 kW

• Rhwystr diogelwch ysgafn

• Cyflyrydd aer ar gyfer panel trydanol

• Meddalwedd CAD / CAM Metalix, Almacam ac ati

• Synhwyrydd LCM (monitor torri laser) ar gyfer canfod tyllu a rheoli colli toriad

PENNAETH TORRI

• Mae'r trawst laser yn cael ei ddanfon i'r pen torri gan gebl ffibr optig.

• Mae'r cebl ffibr optig wedi'i osod ar fewnbwn y pen torri.

• Mae'r laser yn cael ei ddanfon i'r uned ffocysu ar ôl ei alinio yn y collimydd.

• Mae'r trawst laser wedi'i osod i'r ffocws a ddymunir gan ddefnyddio'r lensys yn yr uned ffocysu.

• Mae'r gwydr amddiffyn yn amddiffyn y lensys rhag y gronynnau sy'n cael eu hachosi gan y gweithrediad torri.

• Mae'r mewnosodiad synhwyrydd yn rhan o'r system rheoli drychiad ac mae'n helpu i addasu'r pellter rhwng deunydd a'r pen torri.

• Mae rheolaeth drychiad yn cael ei wirio gyda'r synwyryddion mwyaf manwl gywir yn y farchnad. Mae hyn yn helpu i gynhyrchu toriadau gwell.

• Prif swyddogaeth y cerameg yw amddiffyn y pen torri.

• Defnyddir y ffroenell i reoli'r nwyon cynorthwyol. Mae hefyd yn rhan o'r system rheoli capacitive.

Ffurfweddiad Peiriant torri laser

Llwyfan mecanyddol: y gorchudd, y rheiliau, y sylfaen, sy'n cynnwys fframiau adlewyrchol a rhannau mecanyddol eraill;

Drivetrain: pedwar wedi'u cydbwyso gan y tri chanllaw llinellol manwl uchel a fewnforiwyd, tri sgriw bêl fanwl iawn, gwregys, tri modur stepper a sawl gerau;

Systemau ategol: Mae pwmp dŵr oeri sy'n cylchredeg, cywasgwyr chwythu, ffan mwgwd;

System optegol: tiwb laser, cyflenwad pŵer laser, tri drychau adlewyrchu metel a chydran pen sy'n canolbwyntio.

Manteision

1) Ansawdd trawst rhagorol: Diamedr ffocws llai ac effeithlonrwydd gwaith uchel, ansawdd uchel.

2) Cyflymder torri uchel: Mae'r cyflymder torri yn fwy na 20m / min

3) Rhedeg sefydlog: Gall mabwysiadu'r laserau ffibr mewnforio gorau yn y byd, perfformiad sefydlog, rhannau allweddol gyrraedd 100,000 awr;

4) Effeithlonrwydd uchel ar gyfer trosi ffotodrydanol: Cymharwch â pheiriant torri laser CO2, mae toriad laser ffibr optig dair gwaith yn effeithlonrwydd trosi ffotodrydanol

5) Cost isel a Phrif ddaliadaeth isel: Arbedwch ynni a diogelu'r amgylchedd. Mae'r gyfradd trosi ffotodrydanol hyd at 25-30%. Defnydd pŵer trydan isel, dim ond tua 20% -30% o beiriant torri laser CO2 traddodiadol ydyw. Nid oes angen i drosglwyddiad llinell ffibr adlewyrchu lens, arbed cost cynnal a chadw;

6) Gweithrediadau hawdd: trosglwyddiad llinell ffibr, dim addasiad i'r llwybr optegol;

7) Effeithiau optegol hynod hyblyg: Dyluniad cryno, gofynion gweithgynhyrchu hawdd i hyblyg.

Paramedr Techincal

| Model | ECO-FIBER 3015 / 6KW | |

| Uned Rheoli CNC | System FAGOR 8060 CNC | |

| Echel X (Rack & Pinion) | 3000 mm | |

| Echel Y (Rack & Pinion) | 1500 mm | |

| Echel Z (Sgriw Pêl) | 100 mm | |

| Capasiti torri uchaf | Stee ysgafn | 32 mm |

| Dur gwrthstaen | 16 mm | |

| Aluminyum | 16 mm | |

| Dimensiynau'r darn gwaith | 1525 x 3050 mm | |

| Traws cyflym (echel X ac Y) | 105 m / mun | |

| Cyflymiad | 2.5G (25m / s2) | |

| Cyflymder fector | 148 m / mun | |

| Cywirdeb lleoli llwyr | ± 0.08 mm | |

| Ailadroddadwyedd (echel X ac Y) | ± 0.03 mm | |

| Max. capasiti llwyth | 2450 kg | |

| System CNC Perfformiad Uchel | FAGOR 8060 o Sbaen Brand | |

| Pwer laser | IPG YLS-6 kW o'r Almaen | |

| Modur / gyriant Servo Perfformiad Uchel | FAGOR o Sbaen Brand | |

| Pen Torri Laser | PRECITEC o'r Almaen | |

| Motoreducer | STOBER o'r Almaen | |